Decoding Colors: Understanding the Significance of Color-Coding on Electric Wires

2023-12-05

Introduction:

In the intricate network of electrical systems, where a single wire can carry the power to light up a room or operate complex machinery, color-coding plays a pivotal role in ensuring safety, clarity, and precision. The use of distinct colors on electric wires serves as a visual language that electricians and engineers rely on to navigate the complexities of electrical installations. In this blog post, we will unravel the significance of color-coding on electric wires, exploring how this system enhances safety, simplifies identification, and contributes to the efficiency of electrical systems.

1. Safety First: The Language of Colors:

- Standardization for Safety:

- The color-coding of electric wires adheres to standardized practices set by regulatory bodies and industry standards. These standards are designed to enhance safety by providing a consistent and universally understood system.

- Prevention of Accidents:

- The use of distinct colors helps prevent accidents and mishaps during electrical work. Electricians can quickly identify the purpose and function of a wire based on its color, reducing the risk of errors in connections.

2. Identification of Phases and Functions:

- Phase Identification:

- In alternating current (AC) systems, different colors are often used to identify different phases. For example, in the United States, black, red, and blue wires are commonly used for the three phases of a 120/240V system.

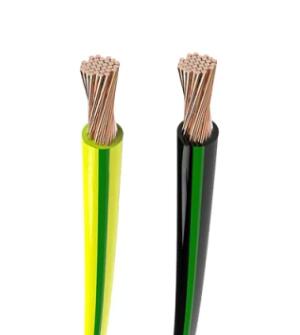

- Neutral and Ground:

- The color white is often used to signify the neutral wire, while green or bare copper is reserved for the ground wire. This consistent color-coding simplifies the identification of these critical components.

- Hot Wires:

- Hot wires, which carry the current from the power source, are often color-coded with black or red insulation. This distinction helps electricians identify the wires that require caution when handling.

3. International Standards and Variations:

- Global Consistency:

- While some color-coding standards are universal, variations exist between countries. International standards, such as the IEC (International Electrotechnical Commission) color-coding, provide a framework for consistency and safety in a global context.

- Customary Practices:

- In addition to international standards, different regions may have customary practices that influence color-coding. Electricians and engineers working in specific locales should be familiar with the local standards to ensure compliance.

4. Low-Voltage Wiring and DC Systems:

- Low-Voltage Systems:

- In low-voltage systems and direct current (DC) applications, color-coding is equally important. Consistent use of colors ensures that even in smaller-scale installations, wires are easily identified based on their functions.

5. Communication and Documentation:

- Ease of Communication:

- Electricians and technicians use color-coding as a form of communication. During installations or maintenance, the use of standardized colors facilitates clear communication, allowing team members to understand the wiring configuration easily.

- Documentation:

- Color-coding extends beyond the physical wires to documentation. Schematics, blueprints, and wiring diagrams often use color-coding to represent different wires and their functions, contributing to clarity in design and troubleshooting.

Conclusion:

The color-coding of electric wires is not merely a visual convention; it is a language of safety, precision, and efficiency within the realm of electrical systems. As electrical installations become increasingly complex, the significance of standardized colors cannot be overstated. It is a visual code that electricians, engineers, and technicians universally rely on to ensure the reliable and safe operation of electrical systems, reinforcing the foundational principle that clarity in color leads to safety in power.